Proactive Planning and Modern Road Inspections

Reactive versus preventive maintenance

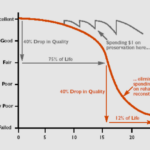

The key to preventive road maintenance is understanding what and when to repair. As shown in Figure 1, road deterioration goes slow in the first years but increases rapidly at some point. The most economical approach is to repair damages before their impact sends the road into a nosedive on this curve.

Moreover, repair budgets are limited. So systematic yearly repairs on all roads are outside the financial capabilities of most road owners. The best way to spend maintenance money is on roads about to enter the phase of accelerated deterioration.

This leads to the following advice:

- Periodic road inspection is the clue to understanding this timing. Taking a periodic snapshot of the state of the road makes it possible to sample the lifecycle curve and to determine where on this curve every single road is.

- Typically roads or even road sections are constructed one by one, at different moments in time. Also the load may vary from road to road in a given area. As such every road has to be inspected in a systematic way. It does not make sense to make predictions of the repair needs of a road based on the state of another (nearby) road.

- Another key requirement is to do the inspections frequently enough: once or twice per year, depending on the traffic load. Only with enough measurement points, the lifetime curve can be sampled reliably and valuable predictions can be made. There are solutions to do thorough automated analysis with dedicated inspection vehicles at price levels well below human inspection. Complementary to this, continuous monitoring is possible based on data from a fleet of cars that cover the road network regularly.

- Run inspections after the winter season. Ice, snow, and salt are the biggest enemies of roads. Deterioration speeds up in winter.

Types of inspection

The above observations lead to the following simple requirements for road inspection solutions:

- Very productive inspection tools are required to cover the entire road network in a rather short period.

- A complete inspection method is required that can observe both categories of defects: cracks (foundation problems) and unevenness (top layer problems).

- A repeatable and objective inspection method is needed: if the inspection process itself has too much variability, it becomes difficult to sample the lifetime curve and to predict the optimal timing for maintenance.

- Numerical results are required to understand the severity of damage. Quantified results make it possible to understand trends and to make comparisons and predictions.

| Human inspection | Camera based inspection | Laser based inspection | 6D road scanning | |

| Productivity | X | ✓ | ✓ | ✓ |

| Completeness | X | X | X | ✓ |

| Repeatability | X | ✓ | ✓ | ✓ |

| Numerical | X | X | ✓ | ✓ |

The most widely spread approach for road inspection is still observation by humans. Road inspectors walk or drive to visually look for defects. Human eyes can see, but cannot measure. Human-operated measurement tools, such as tape measures are not precise enough, slow and dangerous to use. Yet, the main issue is the operator-dependent results as all humans make different interpretations. This makes it very difficult to do proper trend analysis based on such inspection work.

A logical step is to drive around with camera systems, to speed up the inspection process. But also camera images do not give accurate data for measuring and quantifying defects. Potholes and cracks are visible but cannot be sized. Rutting can hardly be seen in images.

This drives the step to laser based systems for digitizing the road. To beat the camera-performance, meaningful laser-based systems have to offer sub-millimeter accuracy and cover the entire road surface.

The optimal solution combines the camera-based and laser-based approach. Camera data is high resolution and enables correct classification of different types of defects. This is then complemented with laser-based data delivering accurate data for sizing defects. 6D roadscanning is an approach that combines camera and laser technology

Hurdles

It is widely proven that road maintenance offers a clear return on investment. The main issues today are:

- Maintenance budgets are too low: if there is no money for maintenance, a reactive approach has to be followed: repairs are only done based on incidents and complaints.

- Incomplete inspection is done: only part of the roads is inspected or too basic methods and tools are used, leading to incomplete and unreliable results.

- Inspection is not translated into a maintenance plan: in some cases, excel tables are filled with inspection results but this data is not analyzed systematically to translate it into a solid maintenance plan.

The remedies are simple:

- Transfer part of the road construction budget to road maintenance budget. After a few years, the impact of this is flushed away since the need for expensive road reconstructions will be lowered.

- Adopt proper road inspection tools, in line with the above explained requirements. Don’t try to drill a hole with a cheap hammer and nail. Buy a drilling machine. It will have itself paid back after just a few holes.

- Use a PMS system (Pavement Management System) to monitor road quality over time and to calculate the most effective use of the available maintenance budget over the entire road network.

Last but not least:

If your road management is too scattered, set up collaborations so practices and tools can be deployed over a larger scale. Countries and regions with the best roads are also the ones that are most advanced with road inspection. Is inspection the chicken or the egg?